Filtration technology utilizing sintered metal media provides to sintered powder filter cartridge excellent performance for separation of particulate matter from either liquid or gas process streams (i.e., liquid/solids and gas/solid separation) in numerous industrial liquid and gas filtration applications.

Sintered metal filter media, fabricated from either metal fibers or metal powders into filtration elements, are widely used them in the chemical process, petrochemical and power generation industries.

Applications require particulate removal to protect downstream equipment, for product separation, or to meet environmental regulations.

Sintered powder filter cartridge have demonstrated high particle efficiency removal, reliable filtration performance, effective backwash capability, and long on-stream service.

Sintered powder filter cartridge can provide particulate capture efficiencies of 99.9% or better using either surface or depth media. Operating temperature can be as high as 1000 °C, depending on the selection of metal alloy.

Along with the filtration efficiency consideration, equally important criteria include corrosion resistance, mechanical strength at service temperature, cake release (blow-back clean ability), and long on-stream service life. These issues are critical to achieving successful, cost effective operations.

The life of such filter media (filter operating life) will depend on its particulate holding capacity and corresponding pressure drop. This accumulating cake can be periodically removed using a blow-back cycle.

The effectiveness of the blow-back cycle and filter pressure drop recovery is a critical function of the properties of the accumulating particles in the cake and the filter media. Depth filtration media configured in a polishing filter may be utilized in those applications with light particle loading.

Technical Specification:

Size: 10”, 20”, 30”, 40”

Fitting: DOE/Code-7/Code-3/NPT/BSP(F)

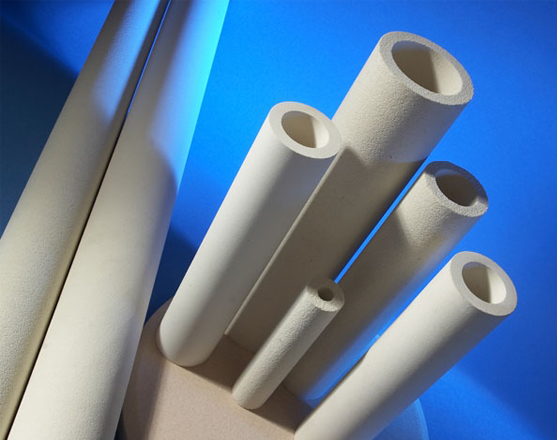

Type: Cylindrical

Micron Rating: 0.2,0.45,1,5,10,20,50 & More

MOC: SS304/SS316/SS316L/Sintered Ceramic/Sintered PP/Sintered PTFE

Gasket: Silicon, EPDM, Viton, Buna-N

Outer Diameter: 64mm(2.5”)

Inner Diameter: 28 mm

Reviews

There are no reviews yet.